Since 1995, our company specializes in the design and manufacture of customized cleaning equipment for a wide range of industrial applications. The product range includes systems for the cleaning of wires, cables, tapes and pipes and cleaning systems for industrial parts cleaning. Based mainly on mechanical or wet-chemical processes, our surface treatment systems and equipment are used worldwide in the manufacturing and processing industries. The strength of our company lies in the open and flexible consideration of each application case, in order to be able to successfully process even unusual requests.

Whether as a comprehensive, "turnkey" system, as an upgrade or as a complement to existing processes, GEO offers a variety of solutions to meet today's quality requirements for the cleanliness of components and continuous profiles.

WELCOME TO

Geo Reinigungstechnik GmbH

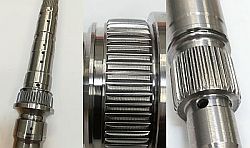

In-line cleaning equipment for wires, tapes, profiles, cables and pipes on an aqueous or mechanical basis

Water-based cleaning and degreasing systems; Single or multi-chamber ultrasonic industrial equipment; laboratory equipment

Deburring, 3D printing finishing, Activation, Matting, Drilling, Quenching & Tempering, Coating, Decoating, Cleaning