Gentle stripping - Primary Wire Wipe (PWW)

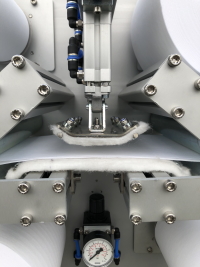

The patented Primary Wire Wipe System (PWW) is a compact, mechanical wiping system for removing visible particulate surface buildup such as dirt and fines, as well as excess drawing material from wires, strands and tapes.

The material to be wiped off passes through two mirror-image, counter-rotating strips of 150 mm wide nonwoven tapes. Wires and strands are guided transversely to the nonwoven tapes. Band shaped material is guided against the running direction of the two nonwoven tapes.

The continuous forward movement and controlled contact pressure of both cleaning belts ensure reliable and comprehensive contact of the material surface to be treated with always fresh and clean nonwoven fabric, a decisive advantage over classic wiping methods using felt discs, sponges, or rags. Unless they are continuously renewed, these collect excess drawing agents and particles, which in the further course can lead to re-contamination and, in the worst case, to surface defects due to the build-up of particles. The system „PWW - SINGLE“ is suitable for wires and strands up to 2.0 mm diameter and tapes up to 120 mm width.

Available for all versions, optionally available gravimetric liquid dosing equipment boost the cleaning effect of the nonwoven tapes.

The control comprised rotary encoder for constant tape speed, and signal exchange for external control. Optional liquid dosing is in ml/min. and displayed by digital potentiometer. Further equipment packages, such as enclosures, complete the features list.

PRIMARY WIRE WIPE

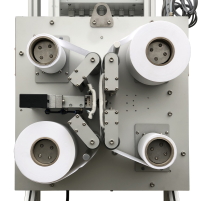

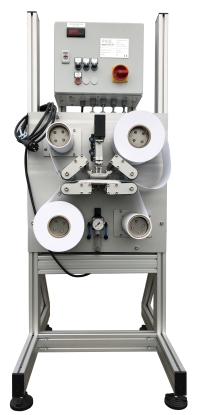

PWW - TWIN

![[Translate to English:] PWW TWIN Drahtreinigung](https://www.geo-reinigungstechnik.de/fileadmin/user_upload/pww_twin_seitenansicht_200.jpg)

In the design as TWIN PWW with four nonwoven rolls and supplemented by a vertically arranged pair of pressure plates, wire diameters up to 4 mm can be treated.

Together with the optionally available gravimetric liquid feed, this configuration can also be used for cleaning with a cleaning agent and subsequent drying.

KFP-V - ERASE of MISPRINTS

from cable & plastic tubing

![[Translate to English:] Kabelfehlprintentfernung](https://www.geo-reinigungstechnik.de/fileadmin/user_upload/kfp_200.jpg)

The KFP-V unit has been designed to remove misprinted text from insulated cables and plastic tubing.

The two stage process consists of first dowsing the cable with a suitable, liquid agent and then passing it through two sets of driven nonwoven tapes that wipe off the print.

The liquid agent is drip fed onto the cable or tubing and evenly spread via static brushes. The cable or tubing then passes through two sets of off-set nonwoven tapes that wipe off the print. The tapes are mechanically driven and run in the opposite direction to the cable flow. The continuously moving, infinitely variable speed of the tapes ensures the tape in contact with the cable is always clean. As each pair of cleaning tapes is off-set by 90 degrees, this together with adjustable pressure rollers ensures the complete circumference of the cable is covered / wiped.

The complete unit is provided with operator friendly, hinged enclosures to which an extractor fan system can be fitted in order to keep the working area free of any fumes.

The KFP-V system is suitable for cable diameters ranging from 5 mm (.20‘‘ ) to 25 mm (1“) / (others on request).

The line speed and consumption of cleaning materials (liquid agent / nonwoven tape / brushes) depend on the cable material and also vary according the amount and density of the misprint to be removed.

Benefits

at a glance

- low space requirement

- low energy requirement

- individually configurable

- wire or tape cleaning

- use with cleaning media optional

![[Translate to English:] PWW SINGLE [Translate to English:] Primary Wire Wipe Drahtreinigung](https://www.geo-reinigungstechnik.de/fileadmin/user_upload/laufrichtung_pww_200.jpg)