Wire coating / quality inspection

Clean welding wire with optimal convey characteristics and perfect ignition behavior. Which welding wire user doesn't want that? In order to achieve a clean wire with ideal conveying properties, at the same time guaranteeing process reliability in processing, clean wire is one of the basic requirements. This is where the manufacturers of welding wires lay the foundation for a successful product.

Often, however, it is the finish, the coating of the welding wire, that ensures optimal welding and soldering processes. Lubricants support clean layer winding on bobbins and in drums and reduce rejects. In the welding process, they reduce undesirable "welds" in the contact tip and improve the convey skills. They thus ensure constant friction values and low conveying resistance as well as a stable arc in the contact tip. A better current transmission reduces micro-arcs, reduces the risk of weld spatter and leads to clearly higher operating times in the conveyor line and contact tip.

In short, fluids for coating welding wire are real miracle cures.

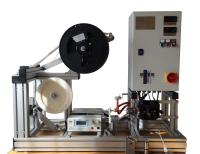

Wire coating systems precisely dose the fluids onto the wire surfaces. The LS-WST device is suitable both for continuous coating and as an inline cleaning device for welding wire.

The LUBRICANT WWF-U300 is a coating agent for welding wire.

LS WST - Wire Lubrication

Cleaning & coating in the smallest space

The LS-WST system applies liquid media or solids dissolved in liquid via a dosing system and a textile tape on wires with round or rectangular cross sections.

The system consists of two modules. In addition to the controller, the drive unit houses a stepper motor for belt transport as well as a dosing system. In the separate process zone, a textile tape is wrapped around the wire. By means of the metering system, liquid is applied uniformly to the wire surface via an applicator. Due to the extremely small dimensions, the process zone can be flexibly integrated into the line.

The dosage is gravimetric or with a micro gear pump. Depending on the installed system, liquids with a viscosity below 100 mPas in the range of 0.1 to 5 ml / min can be applied to the textile tape. The continuous, infinitely adjustable transport of the belt also ensures that always clean tape is in contact with the wire. The LS - WST system is suitable for wire diameters from 0.1 mm (.004 '') to 10 mm (, 4 ").

LS-WST product video on the GEO-Reinigungstechnik YouTube channel.

Lubricant WWF-U300 - coating solution for welding wire

The Lubricant WWF-U300 is a coating agent for welding wire. The lubricant improves the gliding properties in the contact tip, reduces vibration during welding and avoids wire stops due to “micro-welds” in the contact tip.

The Lubricant WWF-U300 is a no water miscible, low viscosity lubricant with a cleaning effect on the basis of non-aromatic carbon hydrogen. Special additives ensure good sliding properties of the wire even at high contact tip temperatures.

Test Equipment for Welding Wire WWTE

The design of the Wire Welding Test Equipment (WWTE) is based on the fact that the quality of a weld is critically dependent on the quality of the welding wire and the arc. Apart from the metallurgical characteristics, the surface quality and their sliding and contact properties play a crucial role. The WWTE provides measurement curves that are relevant for assessing the quality such as feed resistance F (N), welding current I (A), the welding voltage U (V) and the wire speed both directly after the wire feed rollers as well as directly in front of the welding gun.

It is precisely the ratio of those latter two parameters, which in addition to conveying resistance can provide information on the weldability of the wire.

Thanks to the rapid measurement of the wire speed immediately after the conveyor rollers and directly at the welding gun micro-welds in the contact tip and the slip in the conveyor rollers can be reliably detected and informed conclusions on improving the quality of wire can be drawn. The galvanically separated measuring signals are displayed and stored using special software as waveforms on a time axis. They can be issued or printed out separately, one above the other or superimposed. By creating reference measurements and the allocation of a tolerance range fast measurements can be made for quality assurance in the welding wire production.

Welding wire testing system WWTE TV

Quality control of welding wire

The WWTE TV testing device is designed for quality assurance of welding wires both in production and in incoming inspection for welding wire users. The test with the WWTE-TV takes place without generating an electric arc. Welding specialists and a specially set up space with a fume cupboard, light protection, etc. are not required. With its dimensions of 1200 x 600 x 700 mm, the system is designed as a "tabletop device". Since the measurements in the WWTETV test station are carried out without an arc, not only welding wires, but also conveyor hoses and contact tips can be tested comparatively.

For testing with the WWTE-TV, the welding wire is pulled or pushed through a conveying hose (the type can be freely selected) and the contact tip at a speed of 5 to 20 m. With a constant current of 20 A, the delivery resistance and the voltage drop in the contact tip are continuously measured and recorded simultaneously. In order to approximate the conditions that exist in an electric arc, the contact tip can also be heated up to 300 °C.

Video about WWTE-TV system on the YouTube channel of GEO-Reinigungstechnik.

PTD (Paper Test Device)

„Tissue test“

The wipe test is a frequently used method for testing the surface quality of wires before and after processing, such as wire cleaning. This involves the wiping of a wire section with mostly white paper, which is pressed against the running wire surface with the fingers or the back of the hand for a few seconds.

The test can be carried out quickly and easily, and usually allows a simple visual assessment of the cleaning result by means of a "before and after" comparison of the residues in the cloth caused by the wiping.

However, ensuring that all parameters are the same, for an objectively comparable test, is not so simple. The cloth or paper used can vary in structure and in terms of abrasiveness. Even if the test is carried out by only one person, the finger pressure is not constant, and often stronger than necessary. To wipe off contamination, it is usually only necessary to gently touch the wire/profile surface with the paper.

The PTD (paper test device) is a handy tool for performing "tissue tests''. Working with the PTD ensures that the wiping always takes place under the same conditions (force and contact surface) and that the results are objectively comparable. Matching, waterproof paper strips (PSW 1840) facilitate handling. Use of a microscope is recommended, to analyse the traces of abrasion (e.g. microscope unit GEO article no. 2600000111).

Video about PTD (Paper Test Device) on the YouTube channel of GEO-Reinigungstechnik.

STD (Smoke Test Device)

"Smoke test"

Visual determination of hydrocarbons on wire surfaces

A handy method for assessing the cleanliness of wires before and after cleaning is the "smoke test" for the visual determination of hydrocarbons. GEO's STD (smoke test device) is used for the comparative measurement of hydrocarbon quantities on wire surfaces (with a testable wire diameter range of 0.5 to 3mm).

For this purpose, a wire section is clamped between two contacts in the device and heated until it glows by applying a corresponding current strength. The resulting amount of smoke corresponds to the amount of hydrocarbons that were previously on the surface as pollution. The amount of smoke can be determined both visually and quantitatively using a sensor and data logger.

The STD measuring device is a ready-to-use system with an integrated data logger and USB interface. The software and drivers are supplied on USB stick or CD, and are installed on a PC (compatible with Windows 7 to 10) before the system is started up. The licence-free software can be used on multiple computers.

Microscope

Examination of wire surfaces & contact tips

The microscope device is used to examine wire surfaces and contact tips. The microscope is particularly suitable as a supplement to GEO'S WWTE welding wire testing system and can be used on the move due to its small dimensions.

Images of wire surfaces or contact tip holes can be viewed in 2 megapixel size at 20x or 200x magnification on a computer or laptop. With the special software, true-to-scale measurements can be carried out in the micrometer range.

WWF-U300

Advantages & features at a glance

- Can be applied with nearly all conventional coating systems

- Effective even when applied in a thin layer of <10 mg / m2

- Low level of aromatic & Odourless

- Low water hazard class

- Good sliding properties even at temperatures around 300 ° C

Characteristics

- Density at 15 °C > 0,8 kg/l

- Viscosity at 40 °C > 1,8 mm²/s

- Flash point > 61°C

Information

as PDF-Download

-

Lubricant WWF-U300 361 KB

-

SDS Lubricant WWF-U300 289 KB

-

Welding wire test device TV 891 KB

- Download-Archiv

![[Translate to English:] Mikroskopstation Drahtoberflächen](https://www.geo-reinigungstechnik.de/fileadmin/user_upload/mikroskop_illustration.jpg)

![[Translate to English:] Mikroskopstation Drahtoberflächen](https://www.geo-reinigungstechnik.de/fileadmin/user_upload/mikroskop_small.jpg)