LS-WST - wire coating &

cleaning in the smallest space

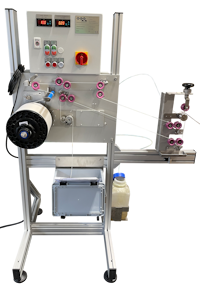

The LS WST uses textile tapes for cleaning or coating wires with round or rectangular cross-sections up to 10 mm.

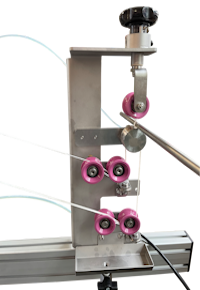

The LS WST consists of two modules, the drive unit for the belt transport and one or two process zones. In the process zone of this wiping system, a woven textile tape wraps around the material surface. The continuously adjustable transport of the strip ensures that there is always a clean wiping tape in contact with the material to be cleaned.

Due to the short process zone and the short contact time between textile and material, as well as the low friction force required for cleaning, an accumulation of metal particles in the cleaning tape with the known effects is avoided, an advantage over comparable mechanical systems.

By means of optionally selectable metering systems, liquid is evenly applied to the material surface via an applicator. Depending on the system, liquids with a viscosity below 100 mPas can be applied to the textile tape in the range from 0.1 to 3 ml/min.

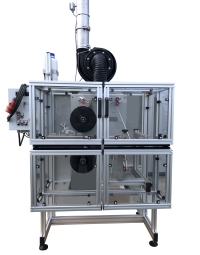

Cleaning of copper conductors before extrusion

GEO has designed the LS-WST-LM specifically for in-line cleaning of copper conductors prior to extrusion. The system is enclosed for use with a volatile solvent. Inside the enclosure, the solvent is evenly applied to the material via a metering unit. The gravimetric liquid dosing is adjustable via a digital potentiometer. Following wetting with the cleaning medium, the material surface is continuously wiped in two process zones. For the extraction of the solvent vapors, the system is equipped, among other things, with a flow sensor and an explosion-proof extraction fan. Due to its compact dimensions, the cleaning system can be easily integrated into existing manufacturing processes.

Benefits

at a glance

- low space requirement

- modular expandable

- high process speeds possible

- easiest operation